__________________________________________________________________

2019 – 2025: 2. S-Bahn Core Route, Munich

To relieve passenger traffic of the existing main line, a second approximately 11 kilometres long main line is being built between Laim station in the west and Leuchtenbergring station in the east. The centrepiece is a seven kilometre long tunnel connecting the newly to-be-built underground stations Hauptbahnhof and Ostbahnhof, with the underground station Marienhof located in between.

For technical details and information on construction progress, please refer to the official DB website for the project:

https://www.2.stammstrecke-muenchen.de/startseite.html

(-> "EN")

Services:

- 2021 – 2025: Team Leader of DB (German Rail) for contract management and

project control / coordination at section Marienhof

- 2019 – 2020: Contract and claim / variation management for the external

engineering consortium in charge of the construction supervision at

section Marienhof

Section Marienhof:

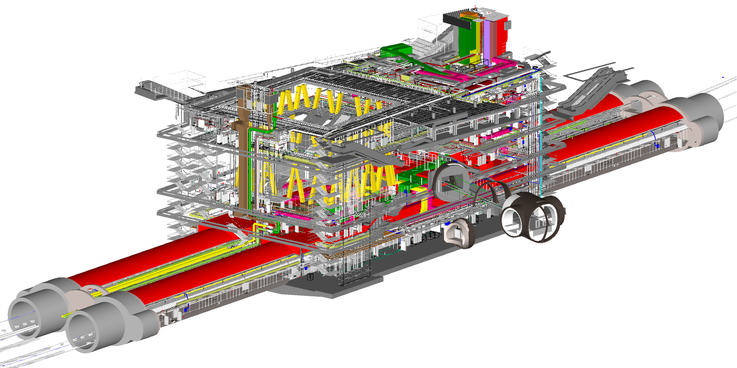

Axonometry of the diaphragm wall box constructed using the cut-and-cover method and the four tunnels for the platform levels. In front: the pedestrian tunnel to the existing subway. All tunnels are being built using the mining method.

____________________________________________________________________________________________________________________________________

2012 - 2013:

BUDAPEST METRO 4, CONTRACT-09: "Integrated Systems, Power

Supply System"

FIDIC (Fédération Internationale des Ingénieurs Conseils) Yellow Book Contract

- Expert report / qualification for the contractor answering the questions raised by

the Arbitral Tribunal with regard to an extension of time / disruption claim

__________________________________________________________________

2006 - 2011:

SECTION U3 NORTH3, Moosach, Germany

Crossing station of German Rail with subway line U3 including a subterranean two story car park and storage sidings

Scope of Construction:

Upfront a sewer was deviated out of the area of the underground car park by means of 86m of pipe jacking (DIN 1200) under the Station of German Rail.

The substructure with a length of 360m length consists of a two story underground car park and a storage siding for the subway underneath. The structures were built whilst at any given time three out of the five tracks of German Rail were in service. Thus German Rail tracks had to be deviated twice and island sites had to be managed.

The walls of the structure were built of single-leaf diaphragm walls (1,20m) and both vertical and inclined (O.D. 1,50m) intersecting bored piles. After excavation at the piles a facing concrete was applied. The restraint length of the walls in the ground necessitated diaphragm walls and bored piles with a length of up to 30m. Due to tight development around the site the top slabs could partly be concreted only in portions, because the road traffic had to be deviated several times. After dewatering of the trough structure, excavation was conducted in two stages. First it was excavated down to the second slab of the car park. After this slab was concreted, excavation down to the base plate was done. During that excavation in part horizontal temporary strutting was installed between the tunnel walls to support the structure for lateral earth pressure.

The tunnel structure stands rectangular to the ground water flow. In order to balance the water levels up and downstream five pairs of shafts were built from bored piles outside the structure and connected with pipes running through the slabs of the car park.

Services:

- Engineer, contract administration and quantity surveillance for structural and

architectural works until subway line U3 went into service and all contract

close-outs were performed, respectively.

Photo above: Feeding of rebar cage for diaphragm wall

Photos below: Inclined bored piles next to existing buildings

Boring piles on the island site between tracks of German Rail

__________________________________________________________________

Photo above: Reinforcing top slab of ticket hall on the island site

Photos below: Intermediate slab portion of car park

Inclined bored piles with bearing pockets for intermediate slabs

__________________________________________________________________

Photos below: Core drilling through diaphragm wall for piping of ground water shaft

Start second excavation stage for storage sidings

Excavation ticket hall with temporary propping

__________________________________________________________________

Photos below: Installation and jacking of auxiliary strutting

Photos above: Works underneath the strutting

Ground freezing

__________________________________________________________________

Photos below: Track works at German Rail

Shuttering works at ramp for car park

Photos above: Reinforcing top slab of ramp

Ramp before opening

__________________________________________________________________

Photo below: Final works storage sidings

Test runs of subway before service date

__________________________________________________________________

2005 - 2009: SECTION U6 NORTH 7, Garching, Germany

Construction of the station "Garching Forschungszentrum" with adjacent lines

- Engineer, commercial close-out of main construction works

- Check of the final invoice of the VOB-Contract

- Assessment of variations and claims

- Preparation of technical expert reports for an insurance coverage claim at court

and an extension of time / disruption claim at court

__________________________________________________________________

2003 - 2007:

SECTION U1 WEST 8, Munich, Germany

Construction of the subterranean crossing station (Lines U1 and U3) "Olympia-Einkaufszentrum" with adjacent tunnels

- Commercial Close-out of main construction works

- Check of the final invoice of the VOB-Contract

- Assessment of variations and claims

- Preparation of an extrajudicial agreement on a disruption claim

- Assessment of owner's entitlement to rectification works of contractor regarding

leakages at the single-leaf diaphragm walls

__________________________________________________________________

1999 - 2001: PUSAR ULAK, Brunei

Technical Project Manager

- Final design of the tunnel structure under a highway built with prestressed

concrete and utilizing the cut and cover method

- Technical support of the site during construction

__________________________________________________________________